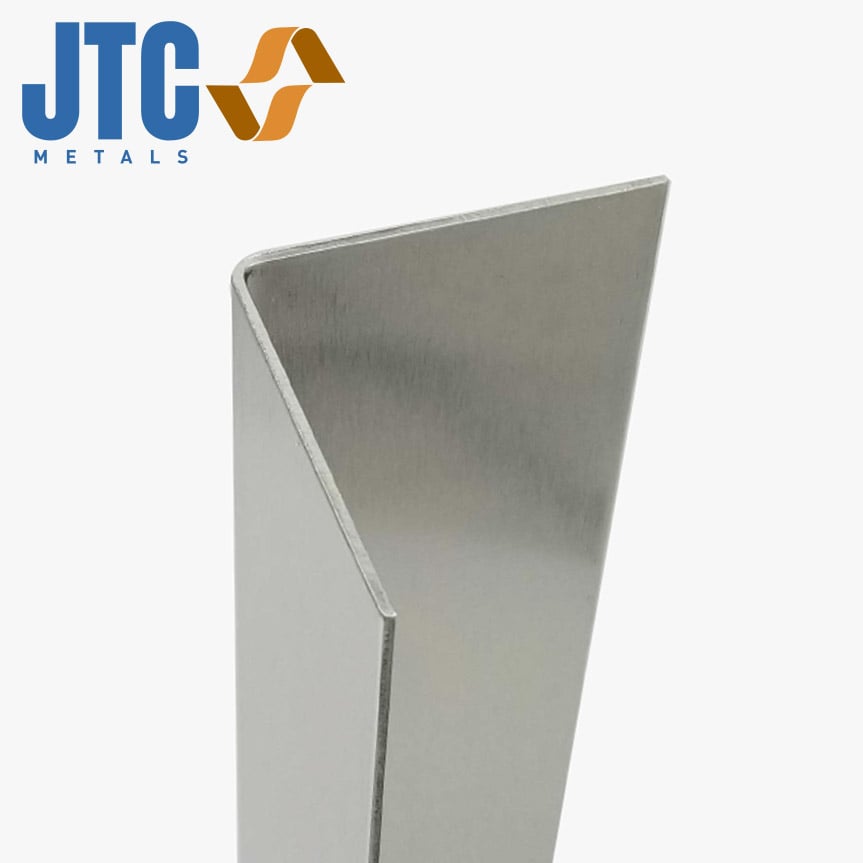

Stainless Steel Corner Guard

Configure Your Corner Guard

- Automatic Quantity Discounts

- Deburred Edges - For Safe Installation

- Accurate Bends - Right Every Time

- Straight Bends - No Canoeing

How You Get Ahead

The corner guards are fabricated with various thicknesses from ultra heavy duty 14ga through 22ga and are available in three finishes. The 18ga is the most popular and provides a good balance of cost, weight, and corner protection. The corner guards are accurately cut and can be purchased as just a basic angle, or with winglets and mounting tape or mounting holes. The products have deburred edges to save your hands and those of your customers.

Accurate bends with no canoeing: This means your corner guards will be hugging the wall all the way up and down. You may have noticed other corner guards don't touch the wall in the middle, and look bowed. This is fairly common and a result of cheaper equipment that doesn't compensate for longer material lengths. Our machines provide accurate bends and fantastic consistency.

Mark-free bends: These aren't as easy to make as one might think. We use a combination of tough, removable protective film on the sheets, rounded shoulders on high precision bend dies, and if necessary, additional cloth or urethane film to ensure you never have to put up with any marks on the metal. Thanks to the consistency of the tooling, you will also not have to worry about "nicks" and/or "offsets" that results in slight differences from tooling sections along the bend.

Deburred Edges: These provide peace-of-mind that you and your crew need not worry about cut fingers and hands. Your customer will be exceedingly grateful especially the maintenance and janitorial personnel who will likely be around and/or touching the corner guards on a regular basis. This one sounds obvious but we have encountered extremely sharp edges in hospitals, high end luxury apartments, labs, correctional facilities, etc, etc. In all these locations, sharp edges are a problem.

You Want Speed? We've got it. Your order will be shipped quickly, typically within 2-3 business days. We understand you need to get the job done, and we understand you don't want to waste time with a flaky supplier. On the off chance there is an issue, we'll contact you to let you know what's going on. There is nothing worse than waiting 2 weeks only to find an order is still 2 weeks from completion.

Shipping and Peace of Mind Typically don't belong together. No doubt you have experienced plenty of issues with small package and/or freight carriers turning your shipment in to a pile of firewood, pretzel, or scrap metal. We have a 0.001% (yes that is correct) damage rate on our freight shipments and a 0.8% damage rate on package shipments via FedEx and USPS. We hate shipping claims and want to make sure you get your product in one piece. Should a carrier choose to play catch with a shipment, toss it off a truck, or just drive over it, we'll get you a replacement out quickly, typically within 24 hours.

Corner Guard Finishes

#4 Brushed Satin Finish: The #4 brushed satin finish is by far the most popular option you'll encounter when using corner protectors. Various names for the same finish are satin, brushed, #4, or nickel finish. and it offers a great looking product that will tend to look good even after being abused for years. The finish is common in restaurants, industrial facilities, hospitals, offices, correctional institutions, commercial facilities, and anywhere tough corner protection is required.

#4 Brushed Black Finish: The black #4 finish is a newer, high end option for the ultimate in protection and luxury. Whether you just want an accent piece or are building a high-rise in the heart of a major city, the black corner guards will provide appealing corner protection that is guaranteed to impress. We will be introducing a PVD finish that is extremely tough and excellent for high wear area.

Random Swirl Finish: For applications where scratching is going to be common, or where you want a unique and attractive finish, the random swirl finish offers a great option. The circular scratches are great for cleaning as any scratches created by aggressive cleaning agents, applicators, Brillo pads, etc won't be an issue.

Corner Guard Sizes

Lengths: Corner guards are available in standard lengths which are 24", 48", 60", 96", and 120" and you can also specify any custom length up to 120". Tolerances re typically +/- 1/32" and angle tolerances are typically +/- 0.5 degrees.

Widths: The corner guards are available with 1", 1-1/2", 2", 2-1/2", 3", 3-1/2", 4" and 4-1/2" legs. If you need a more customized product, we can certainly help. For example, if you need a 1" x 4" angle, please let us know as that's absolutely no problem to fabricate, will not take any longer than a standard corner guard.

Corner Guard Mounting Styles

There is NO need for installation tape. Thanks to advances in adhesives we can offer a fast-grab construction adhesive that grabs and holds. There is NO need for installation tape or screws. Simply apply the adhesive, slap the corner guard in place, hold it for 10 seconds, and you're done.

The corner guards feature either straight legs or 3/8" winglets. The straight legs are great if your walls are exactly square and there is no need to worry about gaps, poor fit, etc. The 3/8" winglets on each leg are bent towards the wall at a small angle. This guarantees a perfect fit every time, and also means they are easier to install. The winglets go by various names, including "wall huggers," "kicks," "riggers" and who knows what else. These are highly recommended unless there is some reason you absolutely can't use them.

The installation tape is an industrial VHB product and if you prep your installation surface correctly, you will never need to worry about loose corner guards. Prepping just means free of dirt, dust, grease, or anything loose or peeling. The tape is pressure sensitive, meaning you need to apply about 15 pounds of pressure via a roller or your hand. The installation tape is on par with fasteners and your crew will save hours of time on installation.

Straight Legs

The straight legs corner guard is your no frills product. It's the hardest to install nicely, and if the corner is not exactly at a 90 degree angle, you may have an unsightly gap on one side or both. Keep in mind the tiny 1/8" radius of the bend will cause the corner guard to stand slightly off the wall unless you have a 45 degree bevel on the corner of the wall. Or, just ensure you can accommodate the radius of the corner guard.

Straight Legs, 3/8" Winglets

The "winglets," "wall huggers," "kicks" or whatever you prefer to call them are the recommended solution for most installations. Each side of the corner guard has a 9 degree bend at 3/8". This is to help ensure you have a nice fitting corner guard even if the wall isn't exactly at 90 degrees and/or there are imperfections in the drywall, paneling, FRP or other substrate you're using. You also don't need to bevel the corners of your walls.

Straight Legs, Mounting Holes

The straight legs with mounting holes features mounting holes 3/4" from the edges and 20" on center. This is another option where your wall has to be perfect 90 degree angle in order to have a nice looking installation.

Legs with 3/8" Winglets, Mounting Holes

The "winglets," "wall huggers," "kicks" or whatever you prefer to call them are the recommended solution for most installations. Each side of the corner guard has a 9 degree bend at 3/8". This is to help ensure you have a nice fitting corner guard even if the wall isn't exactly at 90 degrees and/or there are imperfections in the drywall, paneling, FRP or other substrate you're using.

Stainless Steel Surface Finishes Explained Clearly!

| Q: | What is the #4 Brushed Finish? |

| A: |

The #4 brushed finish is the most popular available today, and typically utilizes . There are various names for it including brushed, polished, satin, and sometimes even nickel finish. It's the de facto industry standard in commercial, industrial and residential applications where aesthetics and longevity are important. It's also the most consistent across batches and is easier to match when upgrading or adding to previous installations. The #4 brushed finish will never fade and is basically ageless, providing you keep it maintained. |

| Q: | What is the 2B Finish? |

| A: |

The 2B Finish is gray in color and somewhat reflective. It looks good initially, but is extremely difficult to keep pristine in applications where it will be handled and/or cleaned frequently. This has no effect on the performance or longevity of the product, but rather the aesthetics. Fingerprints, oils, and various liquids tend to stain the surface of the metal, resulting in uneven coloring and patches with different shades of gray. In addition, the 2B finish is done at the steel mill and may vary in color from batch to batch. |

| Q: | What is the BA Finish? |

| A: |

BA finish, or Bright Annealed finish is similar to a #8 mirror finish or a chrome finish. While quite uniform, the finish is done at the steel mill and may vary slightly from batch to batch of material. You'll find the BA finish on the inside of dishwashers, laundry machines, refrigerators, etc. The bright annealed finish is achieved by heating up and cooling (annealing) in a controlled environment. |

| Q: | Are Stainless Steel Surfaces Anti-Bacterial? |

| A: |

There is a common misconception about stainless steel being anti-bacterial, like copper, brass and bronze, but that is not the case. However, stainless steel is generally cost effective enough and durable enough to be cleaned and/or sterilized frequently without breaking down the surface or material. This is the reason for its popularity in everything from surgical instruments to restaurants. If it isn't destroyed by carelessness, including denting, abrading, drilling holes, etc, stainless steel will provide one of the longest-lasting and best looking finish options available. |